In today’s fast-paced industries, efficiency is everything. Whether you’re in manufacturing, construction, food production, or pharmaceuticals, time lost due to inefficiency can mean wasted resources, increased costs, and a drop in productivity. This is where pre batching comes in—a method that can revolutionize how businesses handle materials, improve accuracy, and streamline operations.

But what is pre batching exactly? In simple terms, pre batching is the process of measuring, organizing, and preparing raw materials or ingredients before they are needed for production. Unlike traditional batching, which happens during the actual production process, pre batching ensures that everything is ready in advance. This reduces downtime, enhances consistency, and minimizes human error.

For industries that rely on precise formulations—like construction (concrete mixing), food processing (bulk ingredient preparation), and pharmaceuticals (precise chemical dosing)—pre batching isn’t just a convenience; it’s a necessity.

At its core, pre batching is the process of preparing and measuring raw materials or ingredients in advance before the actual production process begins. This ensures that when production starts, everything is ready to go, eliminating unnecessary delays and inefficiencies.

To put it in perspective, imagine you’re baking cookies. Instead of scrambling to measure flour, sugar, and baking powder while mixing the dough, you set up all your ingredients in pre-measured bowls beforehand. This way, when it’s time to mix, you can simply pour and combine without pausing to measure. Pre batching applies this same principle on an industrial scale.

Pre batching differs from traditional batching in that:

| Feature | Pre Batching | Traditional Batching |

|---|---|---|

| Timing | Happens before production | Happens during production |

| Efficiency | Reduces downtime | Can cause delays |

| Accuracy | Pre-measured for consistency | Prone to human error |

| Waste Reduction | Minimizes material waste | Higher chance of excess usage |

The Purpose of Pre Batching

So, why is pre batching so widely used? Here are a few key reasons why industries swear by it:

- Increased Efficiency – Production teams don’t waste time measuring or gathering materials, allowing processes to run smoothly.

- Greater Accuracy & Consistency – Pre-measured ingredients ensure that every batch meets the same standards, reducing variability.

- Minimized Waste – By measuring materials ahead of time, companies can reduce excess usage and improve cost efficiency.

- Improved Safety – In industries like chemicals and pharmaceuticals, pre batching helps in handling hazardous materials safely by reducing exposure during active production.

- Scalability – Businesses with large-scale operations benefit from pre batching as it enables them to meet demand without workflow disruptions.

A real-world example? Concrete production. The precise ratio of cement, sand, gravel, and water is critical to the strength and durability of concrete. By pre batching these materials in controlled conditions, companies can ensure consistent quality in every batch they produce.

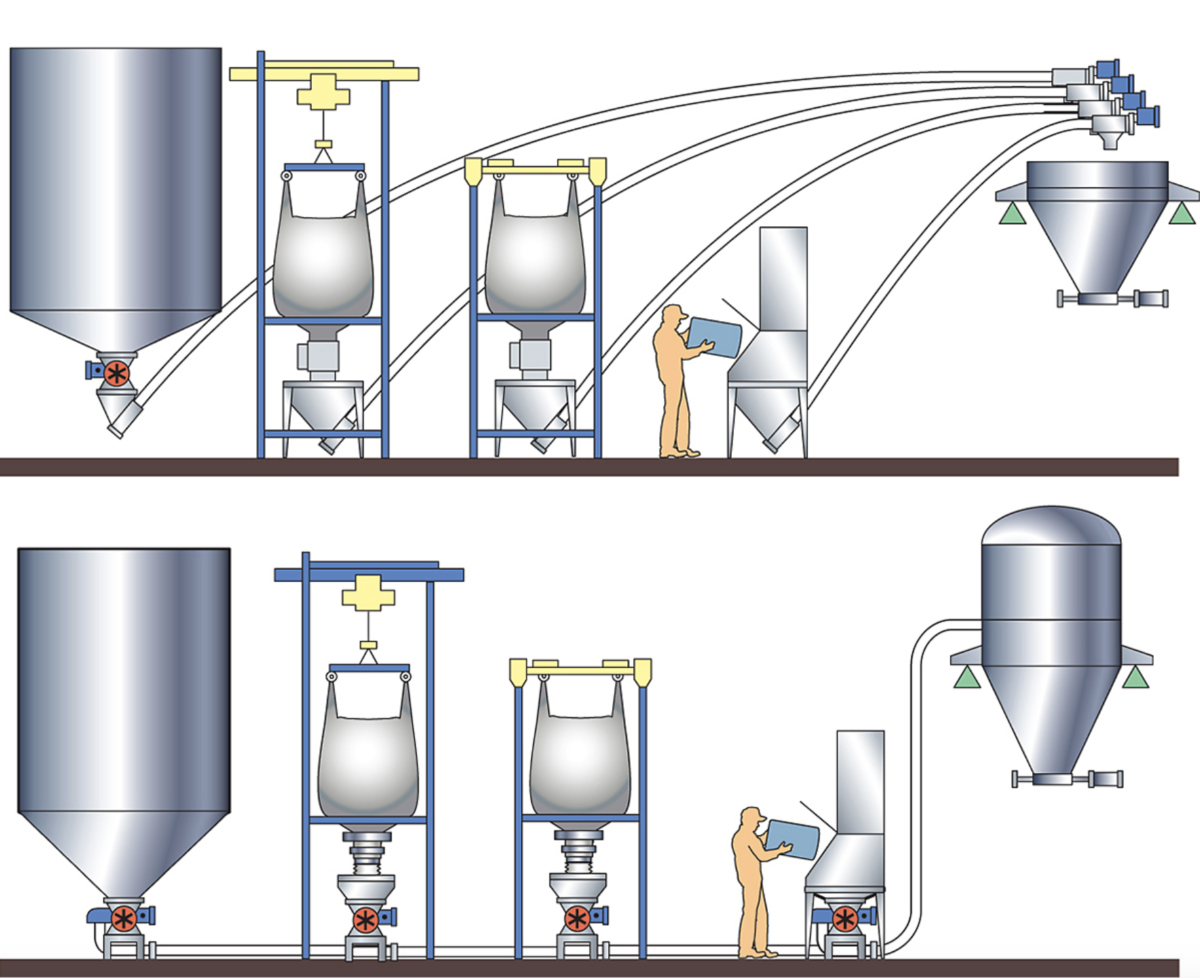

How Pre Batching Works

Now that we’ve established what pre batching is and why it’s so valuable, let’s take a closer look at how it actually works. Pre batching isn’t just about gathering materials; it involves a structured process with multiple steps, specialized equipment, and precise measurements to ensure maximum efficiency.

Steps Involved in Pre Batching

The process of pre batching can vary depending on the industry, but it generally follows these key steps:

- Planning & Material Selection

- Before anything is measured, businesses determine what materials are needed, in what quantities, and for what purpose.

- For example, in food production, this might involve selecting the right type of flour or sugar for a specific recipe.

- Measuring & Pre-Proportioning

- Each ingredient is carefully weighed or measured based on the exact formula required.

- In chemical manufacturing, even a 0.1% variation in ingredient amounts can alter the final product, making accuracy critical.

- Storage & Organization

- Pre batched materials are then stored in labeled containers, silos, or specialized packaging to prevent contamination.

- In industries like pharmaceuticals, pre batched powders or liquids are kept in temperature-controlled environments to maintain stability.

- Distribution & Readiness

- When it’s time for production, materials are transported to the next stage, where they are seamlessly incorporated into the final product.

- In construction, this could mean delivering pre-mixed concrete components to a job site, ready for mixing and pouring.

By separating preparation from execution, companies can prevent delays, errors, and material wastage, making the entire production process more efficient.

Key Components of a Pre Batching System

Pre batching isn’t just a manual process—it relies on a combination of equipment, technology, and automation to function smoothly. The key components of a pre batching system include:

| Component | Function | Industry Examples |

|---|---|---|

| Weighing Systems | Ensures accurate measurement of materials | Pharmaceuticals, Food, Chemicals |

| Storage Silos/Bins | Holds pre-measured ingredients | Cement, Agriculture, Mining |

| Mixers & Blenders | Combines pre-batched materials when needed | Concrete, Food, Chemicals |

| Automation Software | Tracks inventory, schedules batching, and reduces human error | Manufacturing, Warehousing |

Manual vs. Automated Pre Batching

There are two main approaches to pre batching:

- Manual Pre Batching – Workers measure and prepare materials by hand, which is useful for small-scale operations but prone to human error.

- Automated Pre Batching – Uses AI, robotics, and smart sensors to handle measurements, leading to faster, more precise batching in industries like pharmaceuticals and high-volume manufacturing.

The Role of Technology in Pre Batching

Modern pre batching systems are increasingly incorporating automation and data analytics to optimize performance. Many businesses now use:

- IoT-Enabled Batching Systems – Sensors and real-time data tracking help prevent measurement errors.

- AI-Based Predictive Batching – AI can anticipate demand and adjust batching schedules accordingly.

- Cloud-Based Inventory Management – Ensures that materials are pre batched just in time, reducing waste and improving efficiency.

Take Tesla’s Gigafactories, for example. They use fully automated pre batching systems to precisely measure and deliver materials for battery production, ensuring a consistent and efficient manufacturing process.

Pre batching is not just about preparation—it’s about precision, efficiency, and optimization. Whether done manually or through cutting-edge automation, it plays a vital role in streamlining production processes.

Applications of Pre Batching in Different Industries

One of the best ways to understand the real-world impact of pre batching is by looking at how it’s used across different industries. From construction sites to pharmaceutical labs, pre batching plays a critical role in improving efficiency, reducing waste, and ensuring precision.

Let’s explore how different industries leverage pre batching to optimize their operations.

Pre Batching in Manufacturing

In manufacturing, pre batching helps streamline assembly lines and production cycles by ensuring that raw materials are pre-measured and ready for use before they enter the production process.

Key Benefits in Manufacturing:

- Reduces downtime – No waiting for materials to be prepared mid-process.

- Ensures product consistency – Every batch has the same composition, reducing defects.

- Improves efficiency – Pre batched materials mean faster production times.

Example: Automotive Industry

Automobile manufacturers like Toyota use Just-in-Time (JIT) manufacturing, a method that relies on pre batching to ensure that parts are delivered precisely when they are needed, reducing waste and excess inventory costs.

Pre Batching in Construction

In the construction industry, pre batching is essential for concrete mixing and other material preparations. When large-scale projects require massive amounts of concrete, every batch must meet strict quality and strength standards.

How It Works in Construction:

- Cement, sand, gravel, and water are pre-measured according to the project’s specifications.

- Materials are stored in silos at batching plants, ensuring availability.

- Pre batched materials are delivered to the site, ready to be mixed in transit or on arrival.

Case Study: The Burj Khalifa

Dubai’s Burj Khalifa, the world’s tallest building, required 330,000 cubic meters of concrete. Using pre batching, engineers were able to maintain strict quality control, ensuring every concrete mix met the required strength standards.

| Construction Material | Typical Pre Batching Method | Benefit |

|---|---|---|

| Concrete | Pre-measured cement, sand, gravel | Consistent strength & durability |

| Asphalt | Pre batched bitumen & aggregates | Uniform road quality |

| Paint & Coatings | Pre-measured chemical components | Precise color & consistency |

Pre Batching in Food & Beverage Industry

The food industry relies on pre batching for large-scale production where ingredient accuracy is key. Imagine a fast-food chain—they need each burger bun, sauce, and patty to be the same across thousands of locations.

Where It’s Used in Food Production:

- Pre-measured spices and seasonings in snack food production.

- Dough and batter mixing in large-scale bakeries.

- Beverage formulation (e.g., Coca-Cola pre batching its syrup ingredients).

Example: McDonald’s

McDonald’s uses pre batched sauces and pre-portioned ingredients to ensure that every Big Mac tastes the same, whether it’s in New York or Tokyo.

Pre Batching in Pharmaceuticals & Chemicals

When it comes to medicines and chemical formulations, pre batching isn’t just about efficiency—it’s about precision and safety. Even a tiny deviation in ingredient measurement can impact the effectiveness of a drug or the stability of a chemical compound.

How It Works in Pharmaceuticals:

- Active pharmaceutical ingredients (APIs) are pre-measured before being mixed.

- Pre batched materials are stored in controlled environments to prevent contamination.

- Automated pre batching ensures micro-precision, reducing human error.

Case Study: COVID-19 Vaccine Production

Vaccine manufacturers like Pfizer and Moderna use highly automated pre batching to ensure every dose of their COVID-19 vaccine contains exactly the right amount of active ingredient, maintaining efficacy and safety.

Pre Batching in Logistics & Warehousing

Even industries like warehousing and logistics use pre batching to improve efficiency. Instead of picking and packing items on demand, pre batching allows warehouses to group similar orders together in advance, making fulfillment faster.

Where It’s Used in Warehousing:

- E-commerce fulfillment centers (e.g., Amazon pre batching popular products for faster shipping).

- Retail distribution (pre batching seasonal items for store delivery).

- Inventory management (grouping pre-measured bulk orders before shipment).

Example: Amazon’s Robotics-Driven Fulfillment Centers

Amazon uses AI-powered pre batching in its fulfillment centers to group products before they are packed, reducing handling time and increasing shipping speed.

The Versatility of Pre Batching

No matter the industry, pre batching offers universal benefits:

✅ Time Efficiency – Eliminates delays in production.

✅ Cost Savings – Reduces waste and excess usage of materials.

✅ Quality Control – Ensures every batch meets strict standards.

✅ Workforce Optimization – Frees up workers to focus on other critical tasks.

From skyscrapers and automobiles to burgers and vaccines, pre batching plays a crucial role in modern production.

Benefits of Pre Batching

By now, it’s clear that pre batching isn’t just a convenience—it’s a strategic advantage. Whether you’re in manufacturing, construction, food production, or pharmaceuticals, pre batching offers a wide range of benefits that improve efficiency, reduce costs, and enhance product quality.

Let’s break down the top advantages of implementing pre batching in an industrial setting.

1. Increased Efficiency & Productivity

One of the biggest reasons companies turn to pre batching is to speed up production without compromising quality. By having materials pre-measured and ready to go, employees can focus on execution rather than preparation.

How Pre Batching Boosts Efficiency:

- Eliminates material gathering delays – No more stopping production to measure and weigh ingredients.

- Reduces bottlenecks – Especially in assembly lines, where every second counts.

- Minimizes equipment downtime – Machines don’t sit idle while workers measure materials.

Example:

In the automotive industry, companies like Ford use pre batching for parts assembly. Instead of workers searching for components, pre-packaged kits are prepared in advance, allowing them to install parts without interruption.

2. Improved Accuracy & Consistency

In industries like food production, pharmaceuticals, and chemicals, even small variations in ingredient measurements can result in product defects, safety issues, or failed quality tests.

Why Accuracy Matters:

- Ensures product uniformity – Every batch meets the same high-quality standard.

- Prevents costly errors – Incorrect measurements can lead to defective products and wasted resources.

- Supports compliance with regulations – In industries like pharmaceuticals, accuracy isn’t just important—it’s the law.

Example:

Pharmaceutical companies like Johnson & Johnson rely on pre batching to precisely measure active ingredients for medications, ensuring that each dose contains exactly the right amount of medicine.

3. Cost Savings & Waste Reduction

Waste is a huge problem in many industries. Excess material usage, incorrect measurements, and inefficient workflows can result in millions of dollars lost annually. Pre batching helps prevent this by ensuring only the necessary amount of material is used.

| Type of Waste | How Pre Batching Helps Reduce It |

|---|---|

| Material Waste | Pre-measured quantities prevent excess usage. |

| Energy Waste | Reduces machine downtime and unnecessary processing. |

| Time Waste | Workers focus on production rather than prep work. |

Example:

In concrete production, pre batching prevents overuse of cement, which can be expensive and environmentally harmful. Companies that pre batch their materials reduce waste by up to 15% per project.

4. Enhanced Safety & Risk Reduction

Industries dealing with hazardous chemicals, pharmaceuticals, or heavy construction materials must prioritize safety. Measuring or handling raw materials on the spot can expose workers to chemical spills, toxic fumes, or mechanical hazards.

How Pre Batching Improves Safety:

- Reduces direct human contact with dangerous materials.

- Ensures proper handling and storage of chemicals and hazardous substances.

- Minimizes workplace accidents by reducing manual handling errors.

Example:

In chemical manufacturing, pre batching ensures that reactive substances are measured and stored under controlled conditions, preventing dangerous reactions or spills.

5. Scalability for Large-Scale Production

As businesses grow, so does the demand for efficiency and consistency. Without pre batching, scaling up production can become chaotic and inefficient.

Why Pre Batching is Essential for Growth:

- Prepares businesses for high-demand periods (e.g., seasonal surges in food production).

- Allows for rapid expansion without sacrificing quality.

- Optimizes supply chain management by ensuring materials are always ready for use.

Example:

Fast-food chains like Domino’s Pizza rely on pre-batched dough, sauce, and toppings to handle high-volume orders during peak hours while maintaining identical taste and quality across all locations.

Why Pre Batching is a Must-Have

✅ Boosts efficiency – No more production delays due to material prep.

✅ Ensures accuracy – Consistent quality in every batch.

✅ Reduces waste & costs – Only the required amount of materials is used.

✅ Enhances safety – Less direct handling of hazardous substances.

✅ Scales with business growth – Handles increased demand without disruptions.

Pre batching isn’t just a trend—it’s a proven method that saves time, reduces waste, and enhances quality across multiple industries.